Yes, I have made lipsticks. No, I have never made lipsticks the way I did in Japan or have analyzed lipsticks the way I did in Japan.

In USA, making lipsticks in most of the cases are simply blending of waxes, pigments, melt, pour into mold, chill, case it, heat gun over. done. What I did in Japan is something else.

Japanese tend to be very meticulous in everything they do. The product I was making is a new wax-free clear lipstick which I weighted out everything and melt. But before I poured into the mold- the Japanese chemist actually “warmed up” the mold first to prevent “temperature difference” during pouring which can results in uneven stick structure and cause some pigment droplets to kick out. In theory, this makes perfect sense; however, it is not that practical in actual production for scale up.

Prior to pouring the pigmented mixture to the mold, the mixture was put under vacuum suction for two minutes to ensure there was no aeration during mixing. This step is also attention to detail which I have never done it in USA. Usually when the temperature is high enough, air bubbles do not usually get trapped in the mixture. With this vacuum step, it is a double insurance.

Moreover, the mold was cleaned and applied a drop each of ester to ensure easier release of the lipstick bullet when the product is harden. Oddly enough, no chilling table was used to hasten the cooling process for the same reason- ensure product uniformity. In USA, our fast food culture, we would send off the mold to chill quickly so we can go to the next steps.

Once the product is set, the bullets are inserted into the lipstick case waiting to be flamed. Prior to this step, some lipstick bullets are cut off the top layer with a fishnet string if it goes into a supported slim line case. In USA, we do not use open fire in the lab. The most we do is using a heating gun to lightly warm up the surface to ensure the product looks shiny and smooth without nicks or scratched. In Japan, they actually used alcohol lamp for flaming and you have to do it very quickly to avoid fingers being burned.

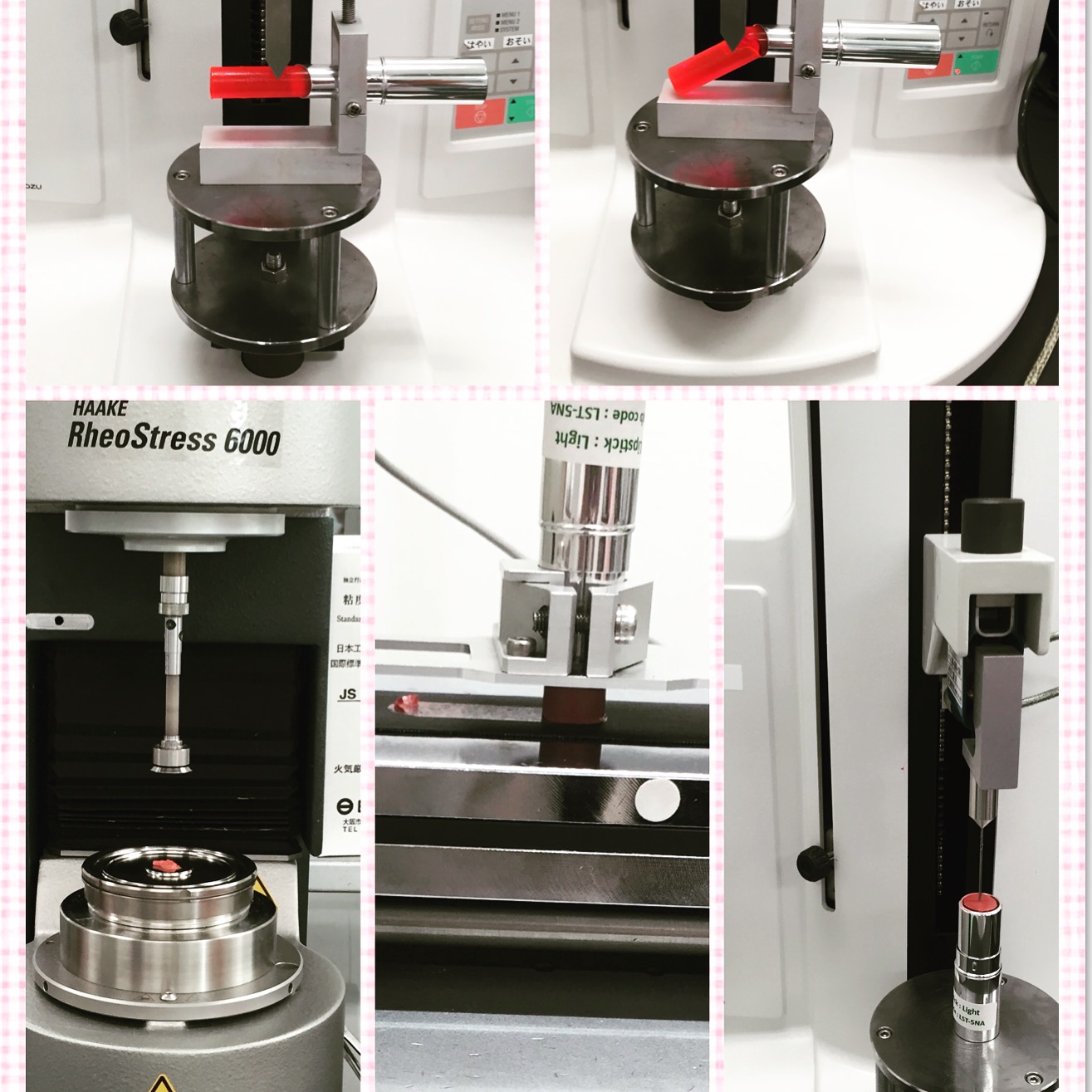

The lipsticks are then checked for bending strength (to make sure it will not break when you apply with force on your lips), friction (to ensure the product will go on your lips smoothly), and hardness (to ensure it will not melt in disaster under high temperature especially if you left in the car). In USA, we do these tests more from sensory points of view but in Japan, they have an instrument for every analysis!

I made four batches of lipsticks- two with the new clear stick technology and two with the traditional lipstick. What kind of lipsticks do you prefer?

There are difference in making products in USA and in Asia. Neither one is better than the other. We ought to appreciate the thoroughness of other culture and also always think how we can translate what we learn in scale up environment and ensure quality.

Ginger